-

SALSICCIA NAPOLI PICCANTE / LUNGA / CORTA / BAST.

Insaccato in budello naturale, segue una leg- gera affumicatura. Prodotto decisamente piccante, ricco di peperoncino e paprica. Può essere legato per conferire la tradizionale forma ricurva. Disponibile in due pezzature: circa 700 gr e 450 gr.

1 Kg

25 pz./cartone -

SPIANATA PICCANTE NATURALE E PREGIATO

Prodotto leggermente piccante è realizzato con parti scelte di suino tritate, impastate e insaccate in budello. La Spianata viene poi pressata per conferirle la tradizionale forma schiacciata. Subisce un processo di asciugamento e stagionatura. Non contiene glutine.

3 Kg

3 pz./cartone -

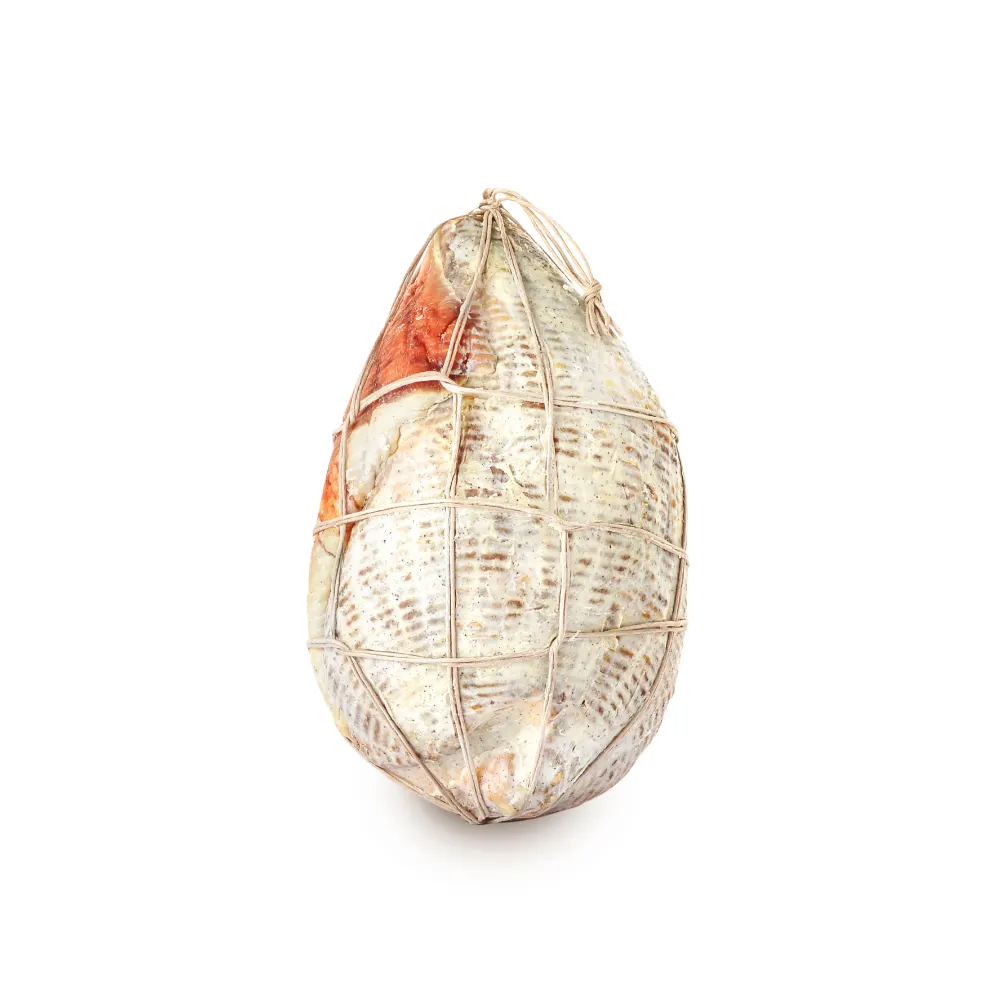

SALAME VENTRICINA

Prodotto ottenuto da parti scelte di suino tritate, impastate e insaccate in budello dalla tradizionale forma a fagiolo. Subisce un processo di asciugamento e stagionatura. Ha un gusto leggermente piccante grazie alla presenza del peperoncino. Non contiene derivati del latte né fonti di glutine.

4 Kg

7 pz./cartone -

SALAME NAPOLI

Tipico salame del Sud Italia, dal sapore leggermente speziato, è realizzato con carni scelte di suino macinate grossolanamente, insaporite con pepe e insaccate in budello. Subisce un processo di asciugamento, stagionatura e leggera affumicatura. Non contiene glutine.

1.6 Kg

8 pz./cartone -

BOCCONCINI

Di piccolo formato, ottimi come antipasto o per uno spuntino veloce, i Bocconcini sono realizzati con parti scelte di suino macinate, impastate ed insaccate in budello. Il prodot- to viene quindi sottoposto ad asciugamento e stagionatura. Non contiene fonti di glutine né derivati del latte.

0.06 Kg

30 pz./cartone -

Salame Nostrano Montanaro

Prodotto stagionato ottenuto da parti scelte di suino rifilate, macinate, impastate e insaccate a caldo in budello naturale. La certificazione di filiera Bergamasca controllata garantisce la provenienza dei capi da allevamenti nazionali, il peso minimo dei capi è di 160 kg e l’età minima è di 9 mesi. Non contiene glutine né derivati del latte.

1 Kg

-

Salame montanaro gigante

Prodotto stagionato ottenuto da parti scelte di suino rifilate, macinate, impastate e insaccate a caldo in budello naturale e legato a mano. La Certificazione di filiera Bergamasca Controllata garantisce: la provenienza dei capi da allevamenti Nazionali, il peso minimo dei capi di 160 kg e l’età minima di 9 mesi. Non contiene glutine né derivati del latte.

3 Kg

-

Salame divino

Prodotto stagionato ottenuto da parti scelte di suino rifilate, macinate, impastate e insaccate a caldo in budello naturale di tipo crespone e legato a mano. Il prodotto è millesimato utilizzando vino Valcalepio rosso DOC. Subisce un processo di asciugamento e stagionatura. Non contiene derivati del latte né fonti di glutine.

0,7 Kg

-

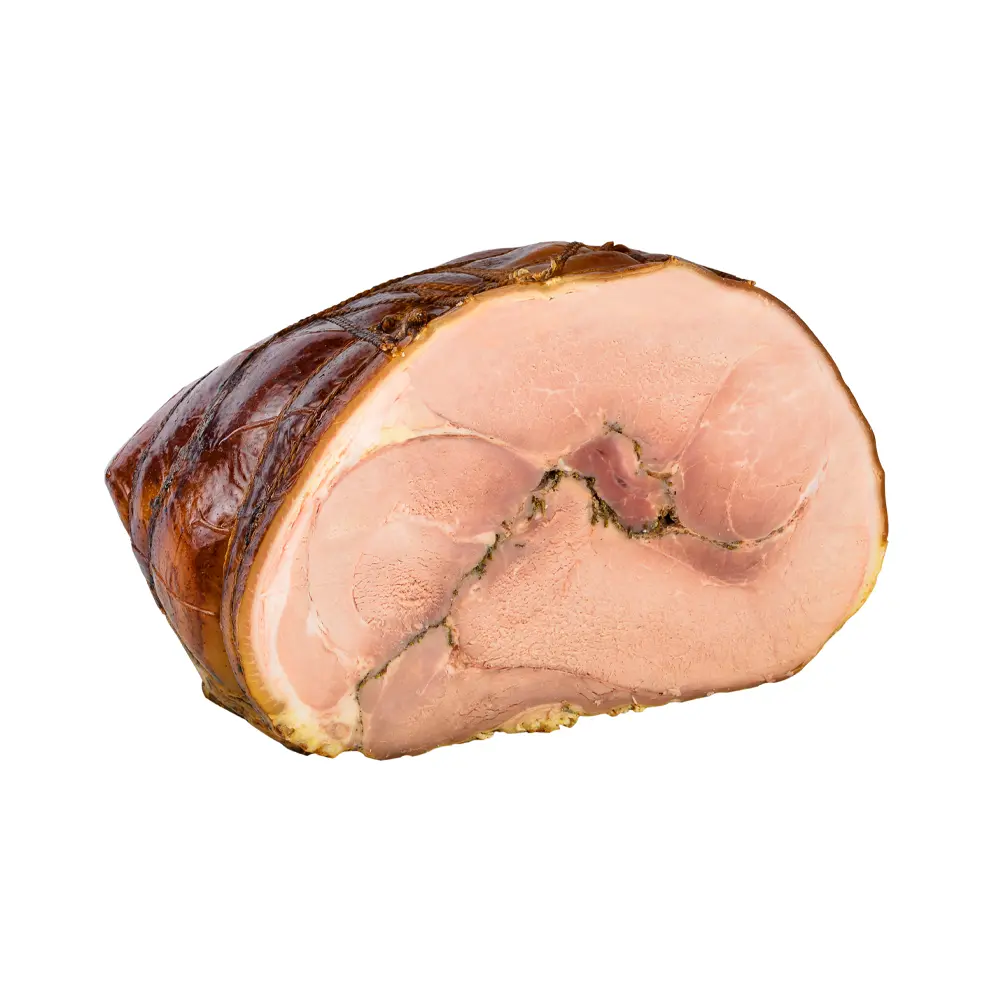

Monello il botto ubriaco pulito a coltello SV

Prodotto stagionato ottenuto dalla parte più nobile della coscia di suino, salata e massaggiata; dopo un processo di asciugamento il prodotto rimane per 30 giorni a riposare nel vino Valcapio DOC.Il prodotto viene poi pulito a coltello prima di essere venduto.

3 Kg

-

Pancetta c/asse antico sapore

Prodotto rustico ottenuto da suini allevati in Italia, la pancetta con cotenna dopo una leggera stagionatura viene pressata tra due stecche di legno di abete. La lavorazione è completamente manuale. Dopo una lunga stagionatura il gusto risulta delicatamente speziato. Non contiene fonti di glutine.

4 Kg – 0,7 Kg

Produzione salumi di qualita IBS Bergamo

Molti ad Azzano ricordano il negozio di macelleria e salumeria Chiesa, a conduzione familiare, posto nel centro del paese. Un luogo ove l'arte salumiera era ben radicata, legata com'era alle antiche tradizione dei contadini che, nel suino, trovavano una completa fonte di alimentazione. Stimolato da un innato senso dell'imprenditorialità, il figlio Ezio Chiesa, sorretto da forte passione, da un esperienza vissuta nel settore sin dalla giovane età, da grande volontà e coadiuvato dalla moglie e poi anche dal figlio, intraprendeva in proprio un'attività di produzione e commercializzazione di salumi. Una piccola Azienda con una grande Missione: riscoprire e riproporre gusti e profumi antichi della genuinità, per anni esclusivo patrimonio delle tradizioni e culture contadine ormai abbandonate, attraverso:

- La Cultura del prodotto, grazie alla conoscenza delle carni, dei loro tagli, delle esatte dosi di salatura e aromatizzazioni naturali.

- La Materia Prima, la cui scelta è fondamentale per il rispetto degli standards qualitativi desiderati.

- La Tecnologia, mediante processi produttivi in grado di coniugare moderna strumentazione e manualità specializzata, a salvaguardia dell'impronta artigianale.

- La Disciplina ferrea del rispetto della qualità.

Il Nuovo Stabilimento

L'affermarsi della specializzazione nella produzione dei salumi tipici, imponeva nuovi ritmi e nuove tecnologie e, con essi, una nuova struttura.

E' dunque nel 1995 che, nelle immediate vicinanze di AZZANO, nell'area industriale appena sorta, viene costruito il nuovo Salumificio.

Su un'area complessiva di 10.500 mq, il nuovo stabilimento si presenta dotato delle più avanzate tecnologie di produzione e stagionatura pur mantenendo quei processi produttivi a impronta artigianale, a tutela della tipicità dei prodotti, che avevano caratterizzato già il vecchio Salumificio.

Aree di lavorazione e trasformazione, celle di asciugamento e stagionatura, a temperatura e umidità controllate, celle di stoccaggio, aree di movimentazione sono tutte realizzate in materiale anatossico con la massima garanzia di rispetto delle norme igienico/sanitarie.